Performance and characteristics

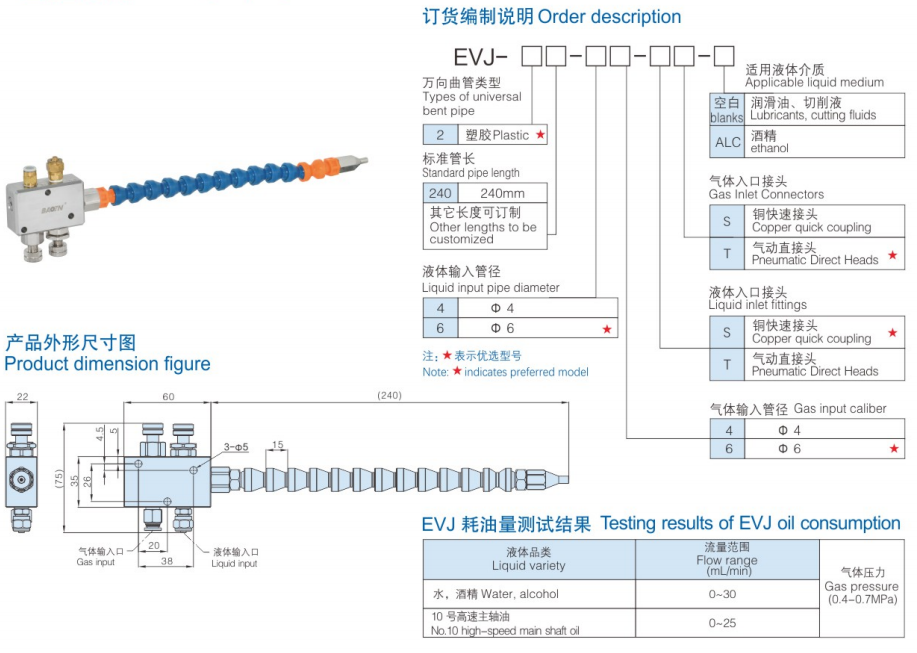

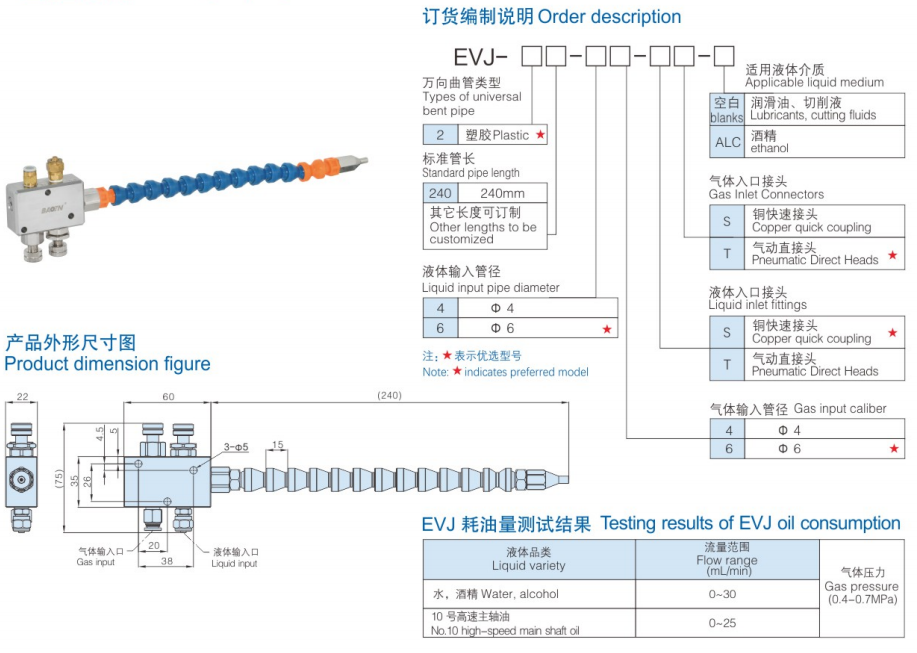

The product shall be operated with the principle of vacuum self-suction, andthe liquid is atomized via the nozzle and air until spraying onto working pieces,tools or bearings and other lubrication points. The cooling effects areexcellent, and lubrication is provided; as well as scrap removal, cleaning andother functions are used to increase production efficiency and improveprocessing quality and reduce losses of machinery tools.Cool down in processing, lubricate, and remove iron scrap in one time.Increase processing rate, save processing time and costs, and reduce wearof knife tools.

Beneficial for assuring processing quality and application effects of knife tools.Processing alloy or super-hard materials achieves smooth and high-precision surface.

Pressurization is enhanced to avoid internal leakage and prolong service life.Different fixing modes are used to match different parts. The air circuit and the oil circuit are opened or closed in linkage, and theoilcircuit is controlled by the air circuit

Attentions:

Clean liquid shall be used.

Corrosive liquid cannot be used.

Scope of gas pressure of the gas pressure source 0.4-0.7MPa (atomizationeffects related to air volume and air pressure)Applicable liquid viscosity: 0-32cSt

Situations for application:

Lathe, drill, mill, grinder, tapping machine, knife tool grinding machine, CNClathe, punch, sawing machine, woodworker machinery and feeding machineetc.