1Liquid level switch and pressure switch (optional) are provided. When oil volume or pressure is insufficient, abnormal signal is output.

2.The panel indicator light indicates power and lubrication status of the oil injection mold.

3.The system is provided with FEED key, and compulsory lubrication is applied.

4.Time setting: single maximum lubrication duration≤2min, and the intermittent time is at least 5 times of the lubricating time.

5.The motor is provided with self-protection to prevent high temperature and overload of motor.

6.No decompression device is provided with resistance-type system, used with proportional joint distributor (Refer to page 29~31).

7.Overflow valve is provided to prevent damage by oil injector and pipeline. Internal fuse is provided to prevent IC board and motor damaged by short circuit.

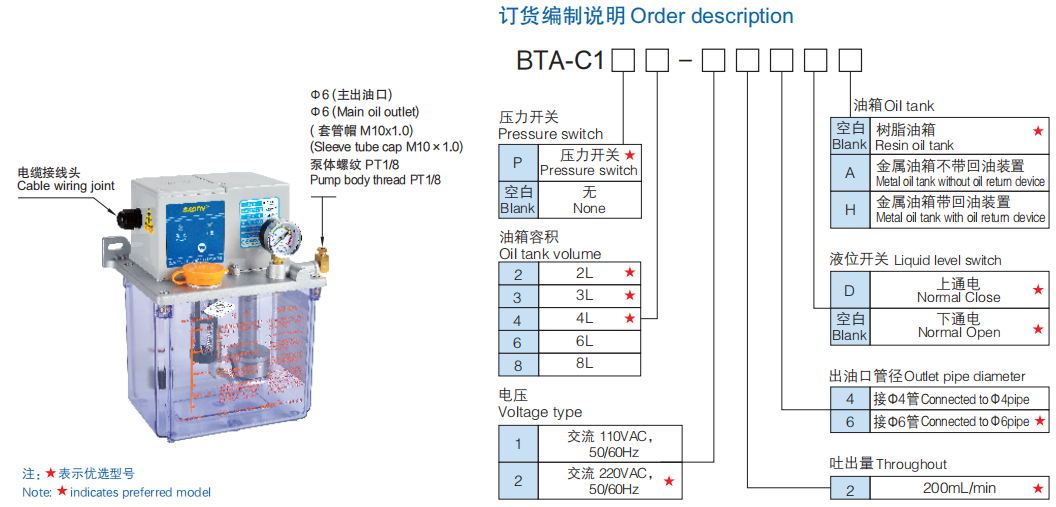

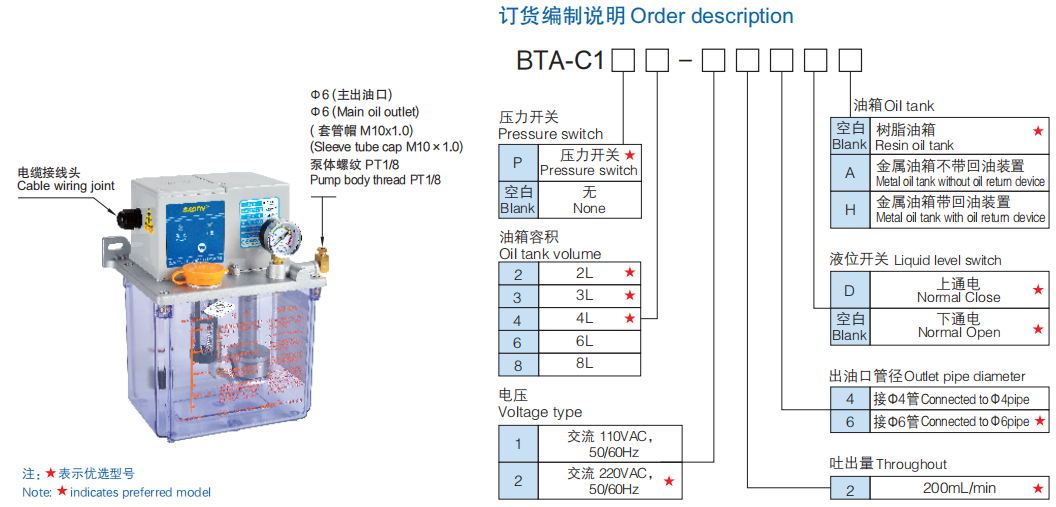

| item | Resistance-type |

| Warranty | 1 years |

| Brand Name | BAOTN |

| Model Number | BTA-C1 |

| Place of Origin | China |

| Application | Automotive Industry, cnc lather |

| Power Source | Electric |

| Pressure | Low Pressure |

| Structure | Gear Pump |

| Outlet Size | 6mm |

| Voltage | 24V 220V |

| Power | 20W |

| Rated throughtout Pressure | 1Mpa |

| Maximum throught pressure | 2.5Mpa |

| Throughout | 200cc/min |

| Oil tank volume | 2/3/4/6/8L |

Company Profile

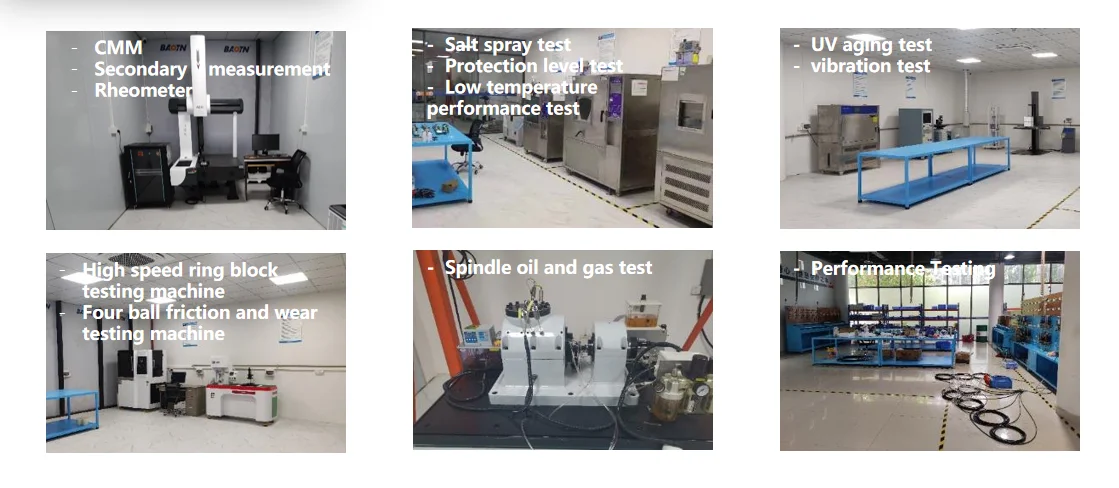

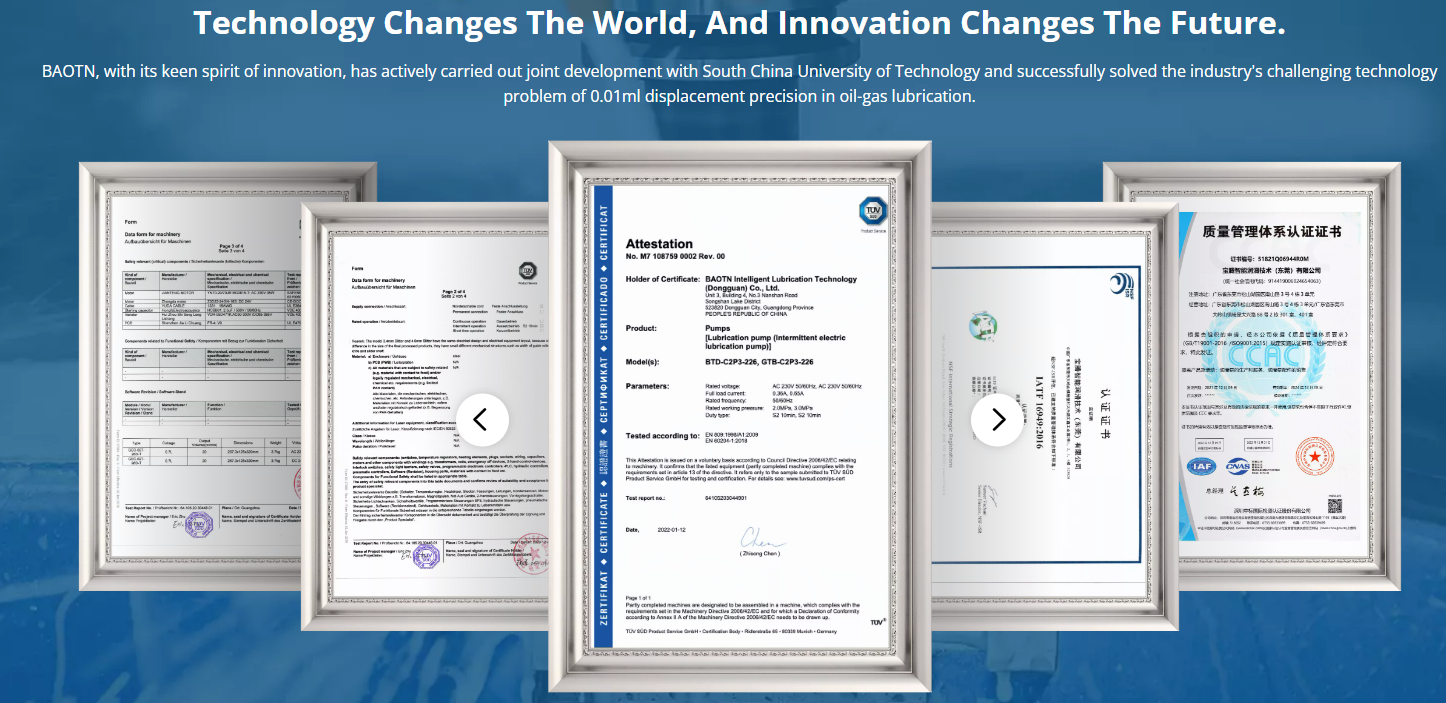

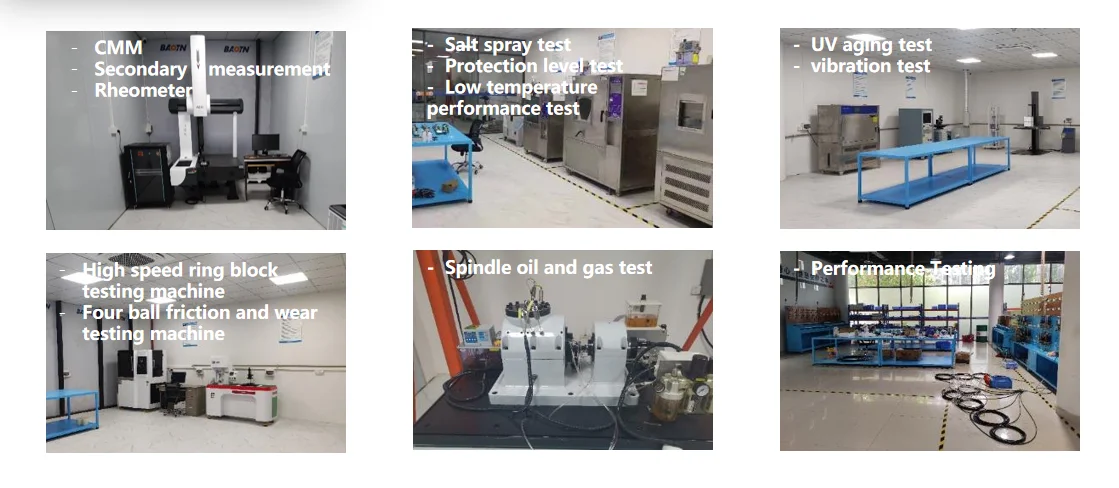

BAOTN Intelligent Lubrication Technology (Dongguan) Co., Ltd. is a high-tech enterprise dedicated to intelligent lubrication systems, located in the beautiful and dynamic Dongguan Songshan Lake Science City, Dongguan, China. Since its establishment in 2006, BAOTN Lubrication has been actively practicing its corporate vision of "becoming a first-class lubrication system and service provider", and has established an extensive service network around the world to meet the needs of global customers. The company's products include thin oil lubrication system, grease lubrication system, oil-air lubrication system and oil mist lubrication system, etc. The products are used in the fields of CNC machine tools, automation, textile, engineering machinery, metallurgy, wind power generation and heavy industry. BAOTN Intelligent Lubrication adheres to the talent and technology as the basis for continuous investment in R&D technology, the introduction of PLM R&D management system, the establishment of the "Tribology Intelligent Lubrication Laboratory" for the product development process to provide a comprehensive test verification. Under the guidance of the quality policy of "Quality First, Continuous Improvement, Full Participation, Customer Satisfaction", we have introduced ISO9001 quality management system, IATF16949 quality management system, ERP system, digitalized on-site signage system, and set up automated precision manufacturing centers to realize intelligent, automated and digitalized production system. production system. The company has won a number of honors such as high-tech enterprises, innovative small and medium-sized enterprises, specialized and special new small and medium-sized enterprises, synergistic multiplying enterprises, group standard�setting unit of grease lubrication system in China's construction machinery industry, Baoteng Engineering Technology Research Center of Intelligent Lubrication Equipment and other honors, and its R&D products have won a number of patents for invention and utility model patents. BAOTN Intelligent Lubrication, focusing on reducing friction and increasing efficiency, and accomplishing customers' core competitiveness.

Certifications

Exhibition