Performance and Features:

1. The system is configured with 3 action modes:

a. Lubricating: when turning on, execute lubricating timing.

b. Intermittent execute intermittent timing after lubricating is completed(Time unit convertible),

c. Memory: in case of power on after power on, resume incomplete intermittent time

2. Lubricating time and intermittent time can be adjusted (Built-in locking function, lubricating and intermittent time can be locked after setting)

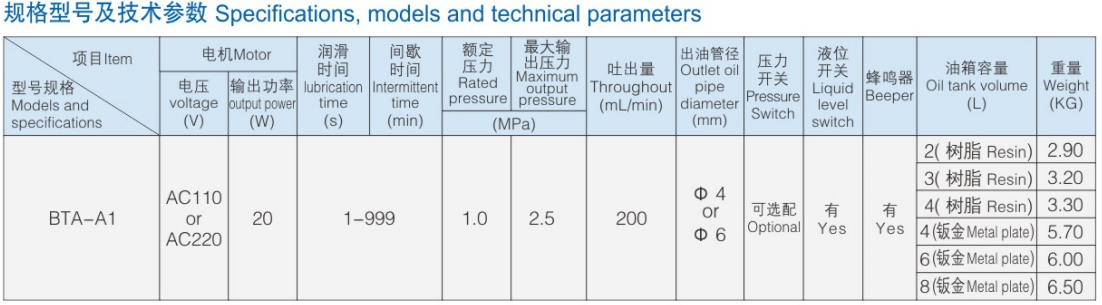

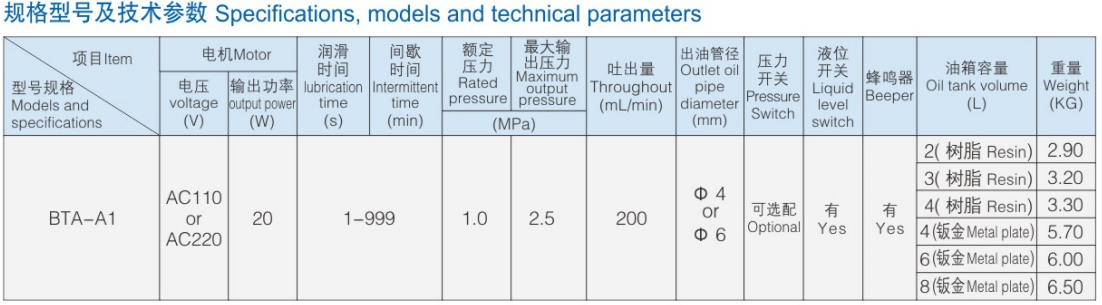

3. Provided with liquid level switch and pressure switch(optional). When oil volume or pressure is insufficient, the beeper alarms and send the abnormal signal out.

a. When pressure is insufficient, Erp is displayed

b. When liquid level is insufficient, Ero is displayed

4. The system time can be configured, LUB lubricating time: 1-999(seconds)

INT intermittent time: 1-999(minutes)(Tailored if specially required)

5. The panel indicator displays lubricating and intermittent status.

6. The system uses RST key to force lubricating or eliminate abnormal reporting signal.

7. Single maximum lubricating time s 2 min, and intermittent time is 5 times of the lubricating time.

8. The motor is provided with self-protection function to avoid high motor temperature and overload.

9. Decompression device is provided with resistance-type system, used with proportional joint distributor.

10. Overflow /s provided to protect oil injector and pipeline from being damaged by high pressure.