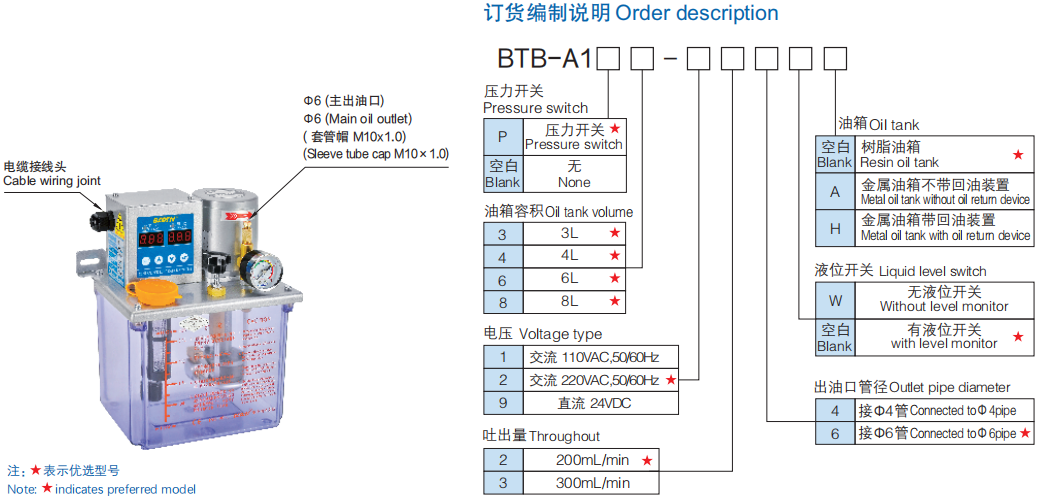

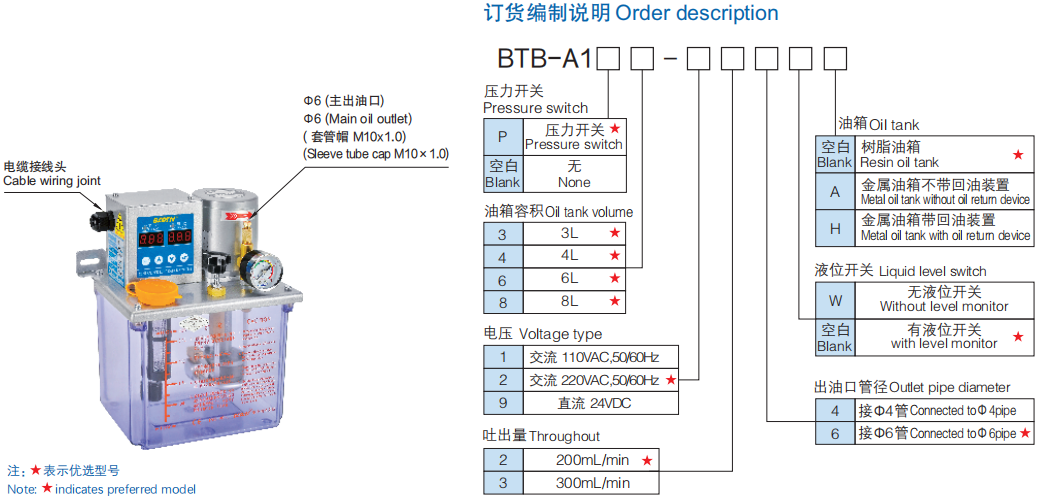

BTB-A1 electric oil lubrication pump

Performance and characteristics

The system is configured with 3 action modes. a、Lubricating: when turning on, execute lubricating timing. b、Intermittent: executeintermittent timingafterlubricatingiscompleted(timeunit converted). c、Memory: in case of power on after power off, resume incomplete intermittent time. Lubricating time and intermittent time can be adjusted. (Built-in locking function, and lubricating and intermittent time after setting is locked). Provided with liquid level switch and pressure switch (optional). When oil volume or pressure is insufficient, the beeper makes sound, send alarm and offers abnormal signal output. a、When pressure is insufficient, Erp is displayed. b、When liquid level is insufficient, Ero is displayed. The system time can be configured, LUB lubricating time: 1-999 (seconds) INT intermittent time: 1-999 (minutes) (tailored if specially required) The panel indicator displays lubricating and intermittent status. The system uses RST key to force lubricating or eliminate abnormal reporting signal. Motor continuously operated No decompression device is provided with resistance-type system, used with proportional joint distributor (Refer to page 29~31). Overflow is provided to protect oil injector and pipeline from being damaged by high pressure.