The GET series centralized lubrication system is a high pressure grease lubrication system,designed,developed and manufactured by BAOTN Intelligent Lubrication Technology (Dongguan) Co., Ltd. for various large and medium-sized machinery. It is suitable for electric power, mining, metallurgy, machine tools, textiles, food, ports, commercial vehicles, construction machinery, heavy machinery and equipment and other industries to ensure the lubrication performance of various mechanical products and extend the service life and accuracy of mechanical equipment.

1.The working cycle of the lubrication pump can be controlled by the host PLC or an independent controller.

2.It is equipped with a pressure regulating valve device, which can independently set the working pressure of the lubrication pump to ensure its work safety.

3.Equipped with low oil level transmitter, normally open contact or normally closed contact can be selected according to the system.

4.Please use a refueling gun or a refueling machine to add grease to the oil storage tank of the lubrication pump to prevent impurities and air from mixing into the lubrication system, thereby improving the use effect of the lubrication system.

5.The lubricating system is equipped with a pressure switch, which can effectively monitor the lack of pressure such as interrupted flow and leakage of the lubricating system pipeline.

6.The material of the pump body is aluminum alloy, which has excellent physical properties such as high strength and light weight.

7.Applicable lubricant range (at standard temperature): lubricating oil≥ N68, grease NLGI 000~2

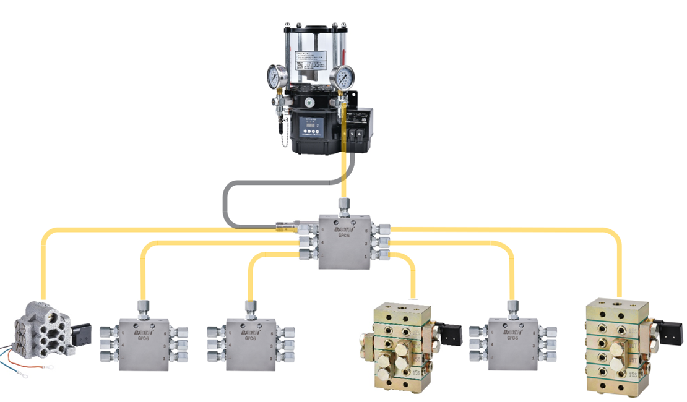

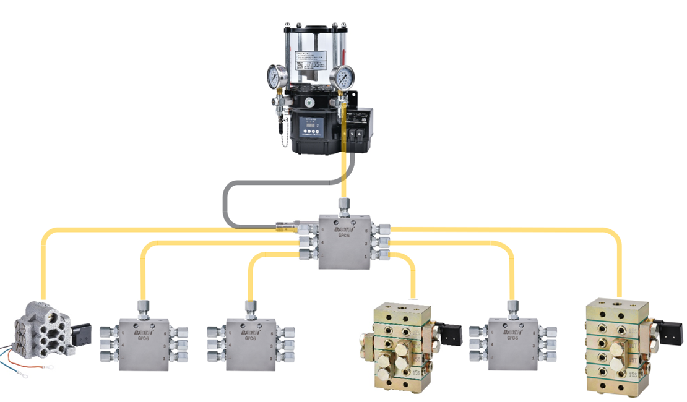

8.The grease outlet can be directly connected to the lubrication point, or it can be connected to a progressive distributor for multi-point lubrication. Use oil scraper oil pressure device.

9.A single pump body has 1-5 grease outlets to choose from, and the selectivity is large.

10.Equipped with safety relief valve and pressure gauge to monitor the working condition of the system at any time.

11.There is no pressure relief valve device in the progressive system, it needs to be used with the GPB/GPC/GPD distributor.

| item | Progressive |

| Warranty | 1 years |

| Brand Name | BAOTN |

| Model Number | GET |

| Place of Origin | China |

| Application | Automotive Industry, cnc lather |

| Power Source | Electric |

| Pressure | High Pressure |

| Structure | Gear Pump |

| Outlet Size | 6mm |

| Voltage | 12V 24V 110V 220V |

| Power | 60W |

| Rated throughtout Pressure | 3Mpa |

| Maximum throught pressure | 16/25/35Mpa |

| Throughout | 2/2.8/4ML/min |

| Oil tank volume | 1.5/2/4/6/8L |

Company Profile

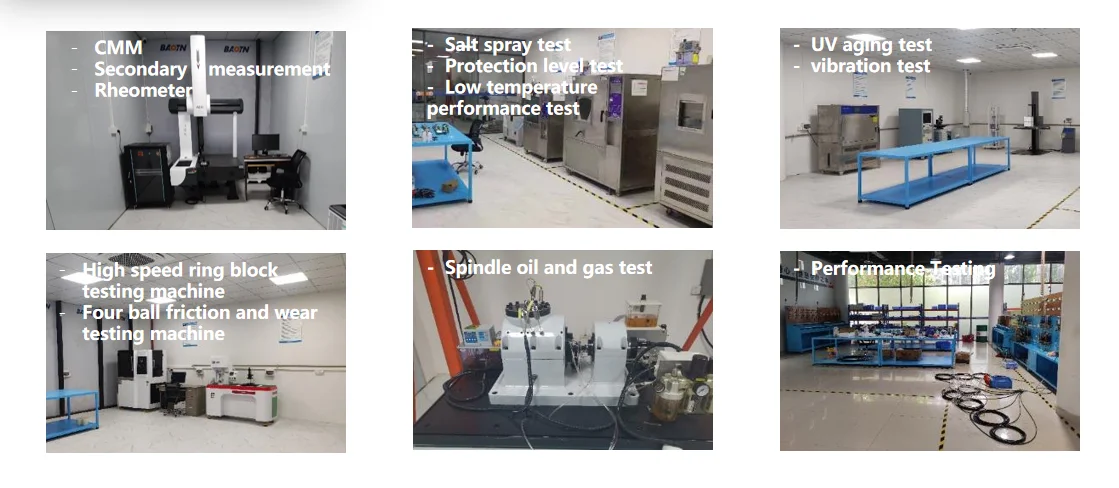

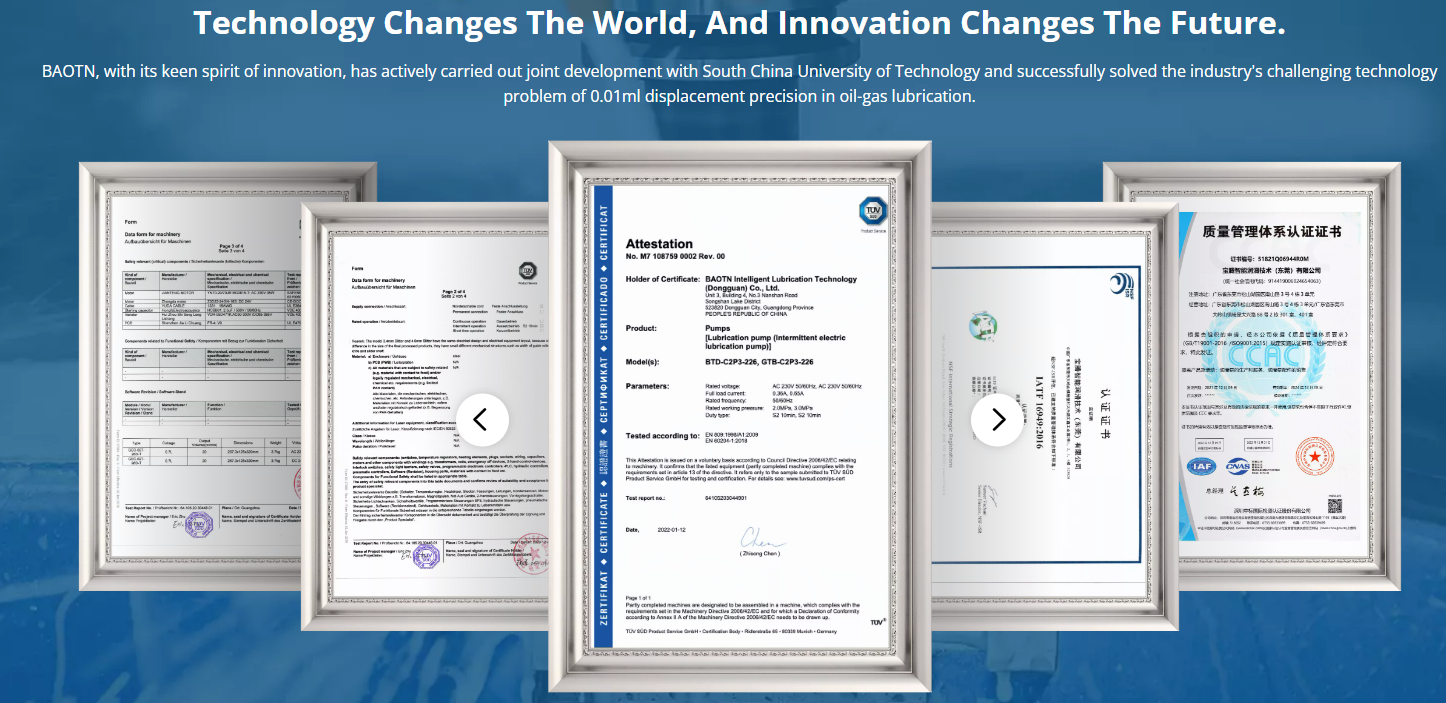

BAOTN Intelligent Lubrication Technology (Dongguan) Co., Ltd. is a high-tech enterprise dedicated to intelligent lubrication systems, located in the beautiful and dynamic Dongguan Songshan Lake Science City, Dongguan, China. Since its establishment in 2006, BAOTN Lubrication has been actively practicing its corporate vision of "becoming a first-class lubrication system and service provider", and has established an extensive service network around the world to meet the needs of global customers. The company's products include thin oil lubrication system, grease lubrication system, oil-air lubrication system and oil mist lubrication system, etc. The products are used in the fields of CNC machine tools, automation, textile, engineering machinery, metallurgy, wind power generation and heavy industry. BAOTN Intelligent Lubrication adheres to the talent and technology as the basis for continuous investment in R&D technology, the introduction of PLM R&D management system, the establishment of the "Tribology Intelligent Lubrication Laboratory" for the product development process to provide a comprehensive test verification. Under the guidance of the quality policy of "Quality First, Continuous Improvement, Full Participation, Customer Satisfaction", we have introduced ISO9001 quality management system, IATF16949 quality management system, ERP system, digitalized on-site signage system, and set up automated precision manufacturing centers to realize intelligent, automated and digitalized production system. production system. The company has won a number of honors such as high-tech enterprises, innovative small and medium-sized enterprises, specialized and special new small and medium-sized enterprises, synergistic multiplying enterprises, group standard�setting unit of grease lubrication system in China's construction machinery industry, Baoteng Engineering Technology Research Center of Intelligent Lubrication Equipment and other honors, and its R&D products have won a number of patents for invention and utility model patents. BAOTN Intelligent Lubrication, focusing on reducing friction and increasing efficiency, and accomplishing customers' core competitiveness.