Performance and characteristics

1,The working cycle of the lubrication pump can be controlled by the host PLC or an independent controller

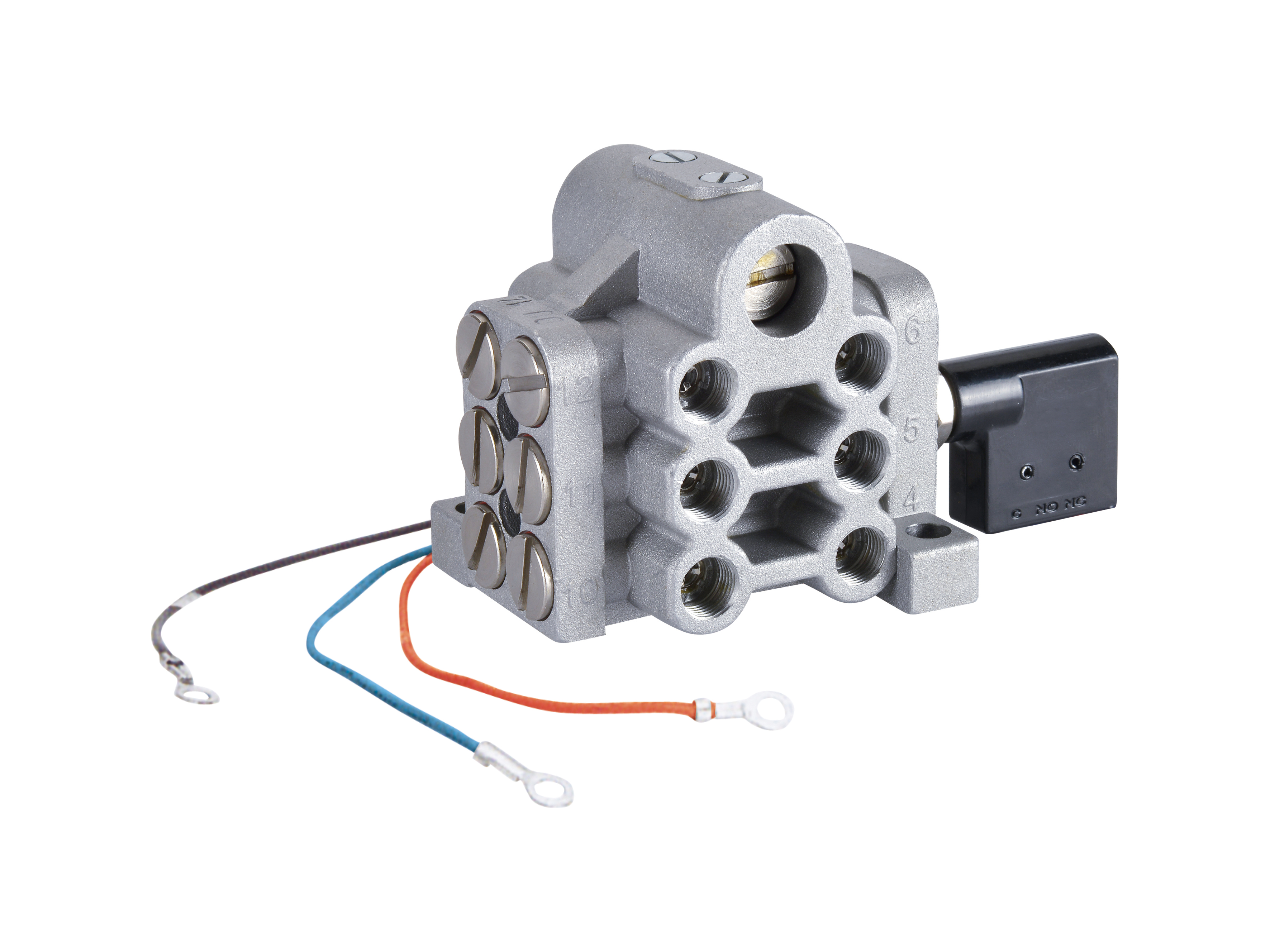

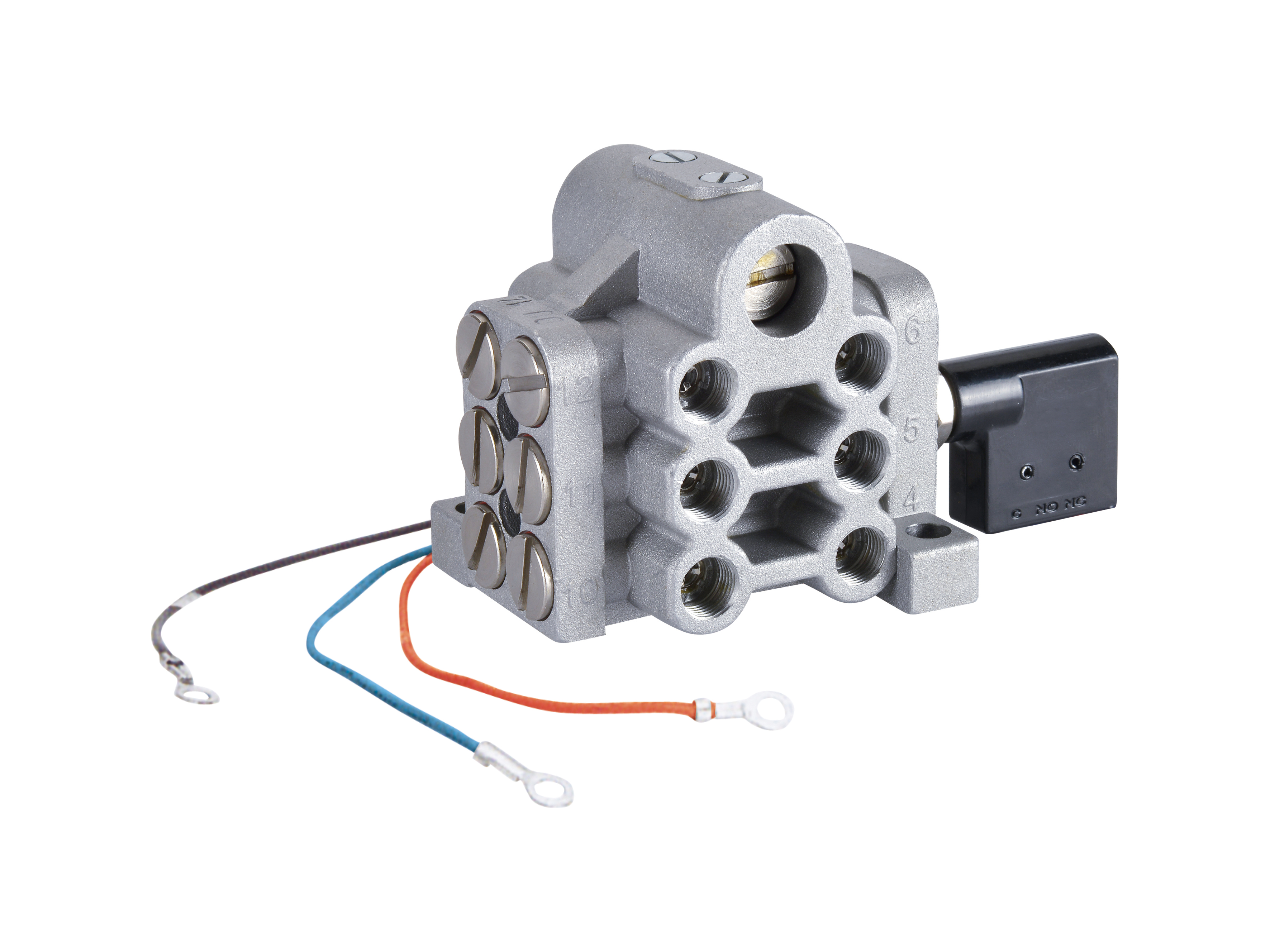

2,It is equipped with a pressure regulating valve device,which can independently set the working pressure of the lubrication pump to ensure its work safety.

3,Equipped with low oil level transmitter,normally open contact or normally closed contact can be selected according to the system.

4,Please use a refueling gun or a refueling machine to add grease to the oil storage tank of the lubrication pump to prevent impurities and air from mixing into the lubrication system.

5.The lubricating sytem is equipped with a pressure switch,which can effectively montinor the lack of pressure such as interrupted flow and leakage of the lubricating system pipeline.

6.The material of the pump body is aluminum alloy ,which has excellent physical properties such as high strength and light weight.

7,Applicable lubricant range (at standard temperature):lubricating oil ≥N68,grease NLGI 000#~2#

8,The grease outlet can be directly connected to the lubrication point,or it can be connected to a progressive distributor for multi-point lubrication.

9,Use oil scraper oil pressure device

10,A single pump body has 1-5 grease outlets to choose from,and the selectivity is large

11,Equipped with safety relief valve and pressure gauge to monitor the working condition of the system at any time

12,There is no pressure relief valve device in the progressive system,it needs to be used with the GPA/GPB/GPC distributor