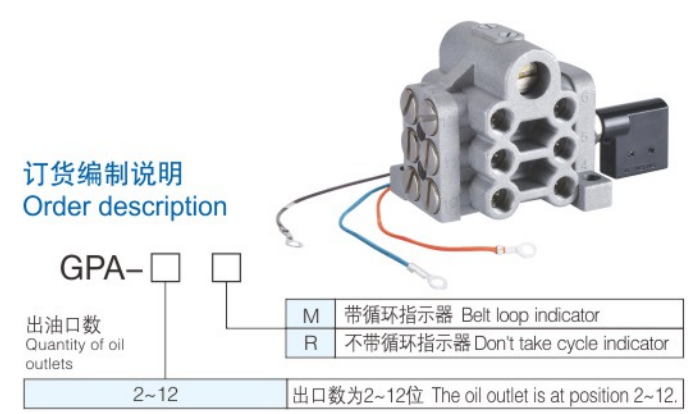

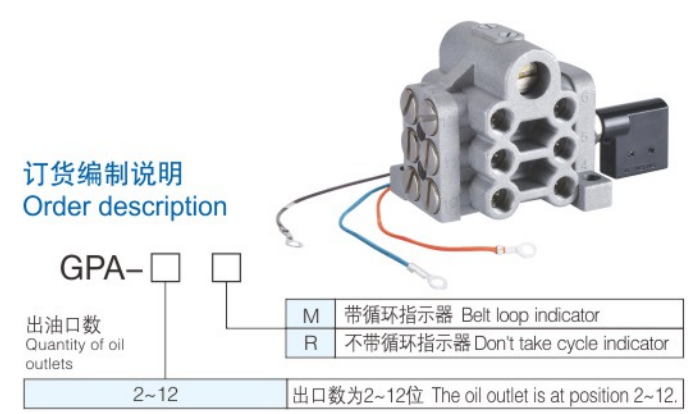

GPA Progressive grease distributor

Features of Grease Union Dispenser butter distributor

• Notes of technical parameters of the GPA distributor

• Maximum nominal pressure: 60kgf/cm2

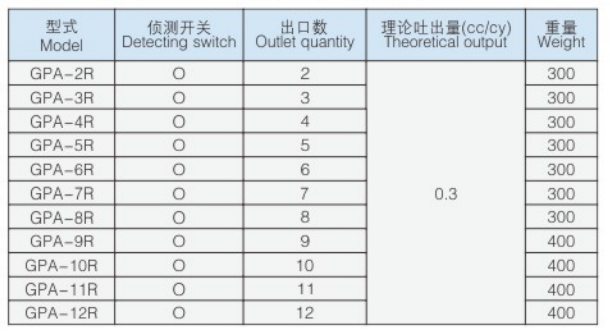

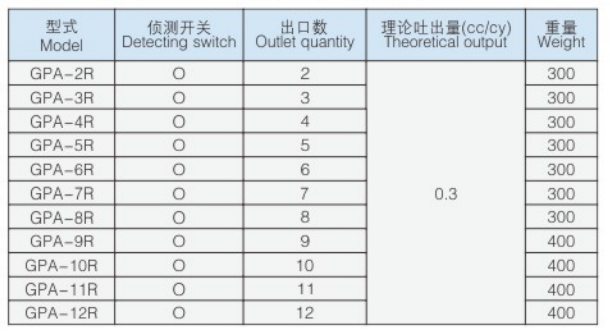

• Standard displacement: 0. 3cc/cy

• Applicable lubricant scope (under standard temperature): thin oil lubricant>=68, and oil grease000#-0#

• Working environment temperature:-10℃ to+60°

• Maximum cycling rate of plunger pair: installed with mechanic cycle indicator: 60 cy/min

• Maximum cycling rate of plunger pair: 200cy/min•

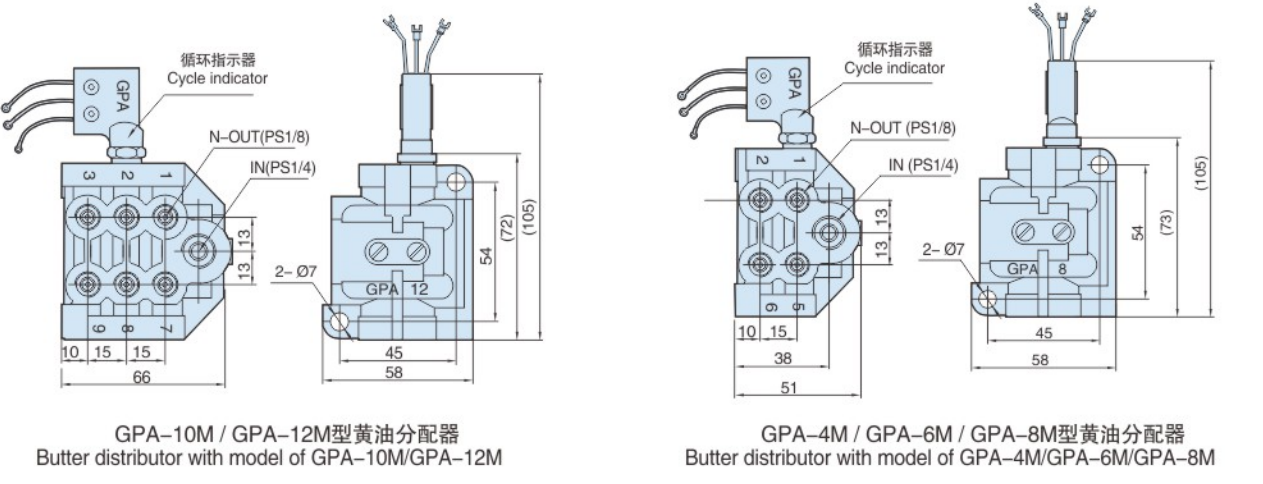

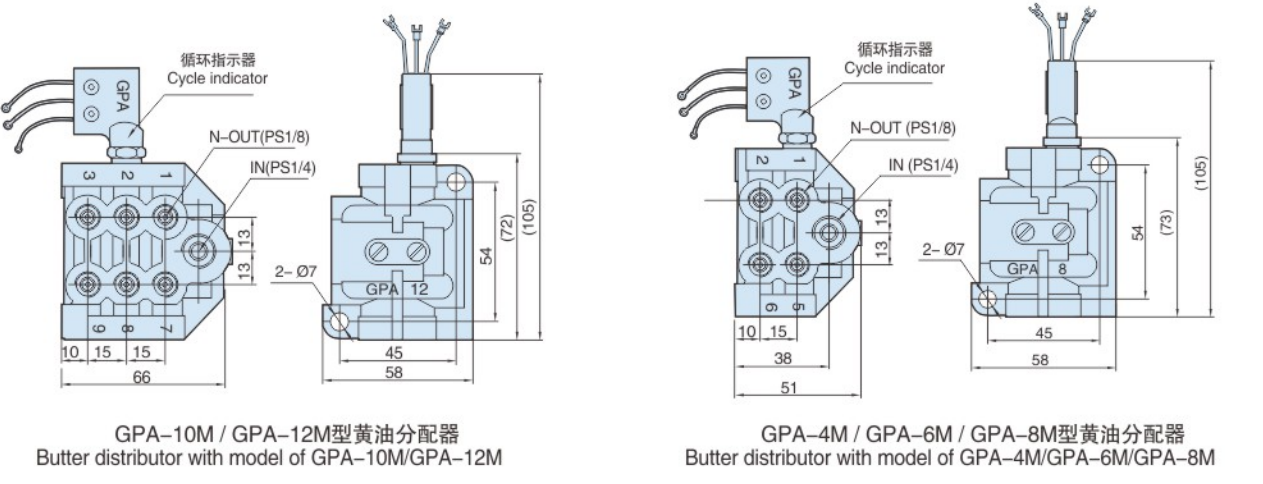

• Number of lubricating points for each set of distributor: 2.3.4.5.6.7.8.9.10.11.12

• Maximum pipe diameter and length of each distributor: 4mm, length of 0.5-2.5m

• Shell material: aluminum alloy

Scope of application

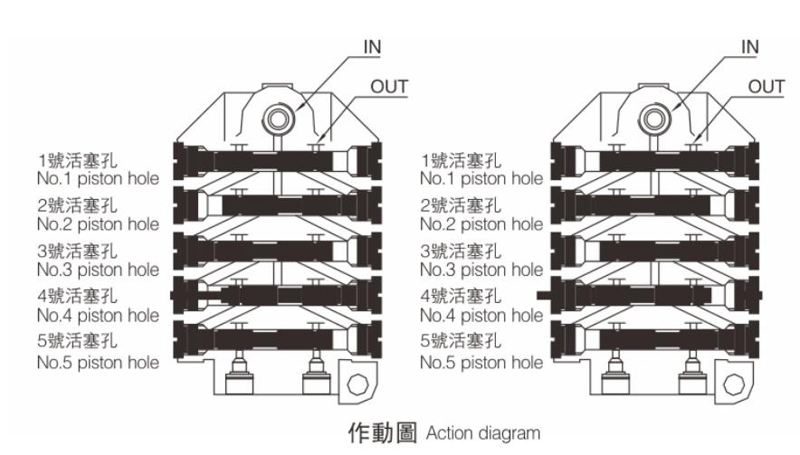

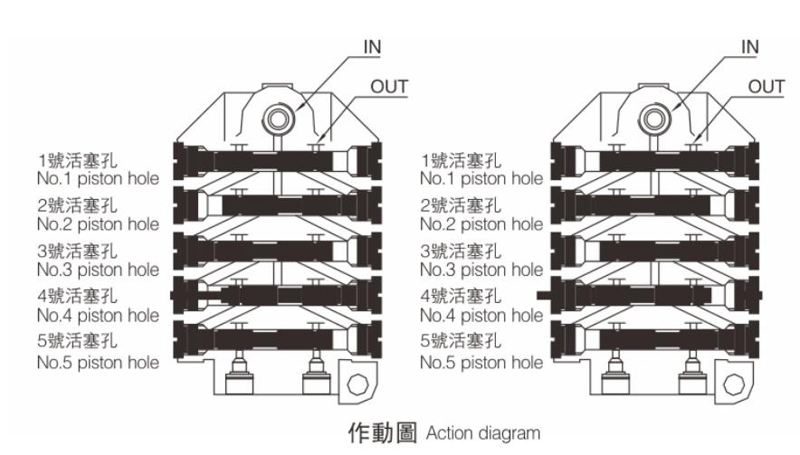

The progressive butter distribution is a kind of oil volume distributor with advanced design and proper structure. It composes an one-way lubricating system with manual, electric and pneumatic lubricating pump, and is an ideal product suitable for medium and small-sized lathe tool and plastic machinery and equipment and similar conditions. A set of BU distributor provides lubricating for 4,6,8,10 or 12 lubricating points. The BU distributor has only one displacement of 0.3cc/cy.

Remarks: as for oil outlets of the distributor, any oil outlet cannot be blocked; otherwise, the normal operation can be affected, and the distributor is damaged.