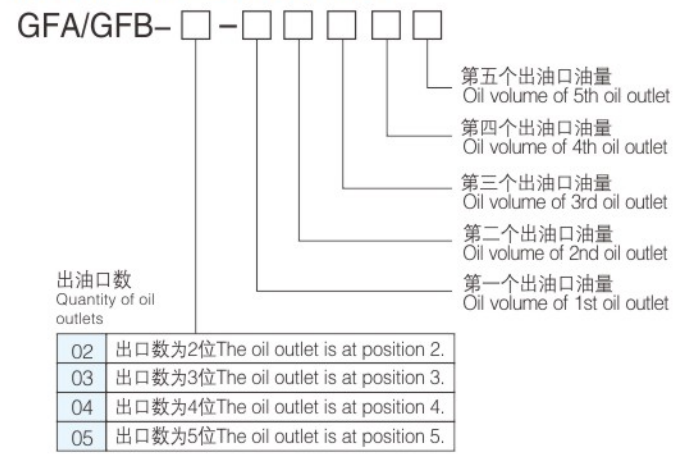

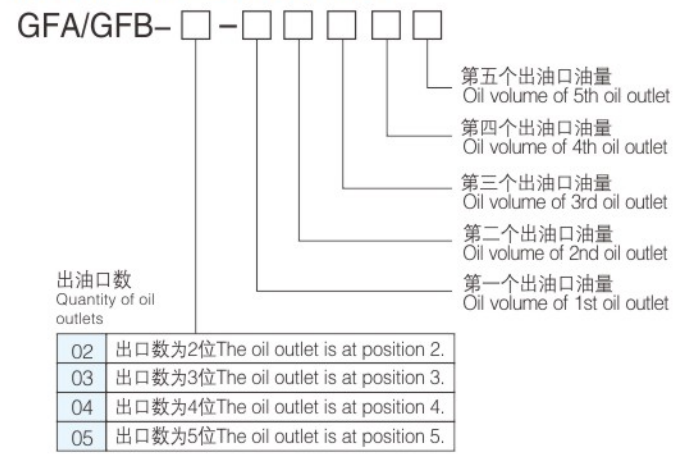

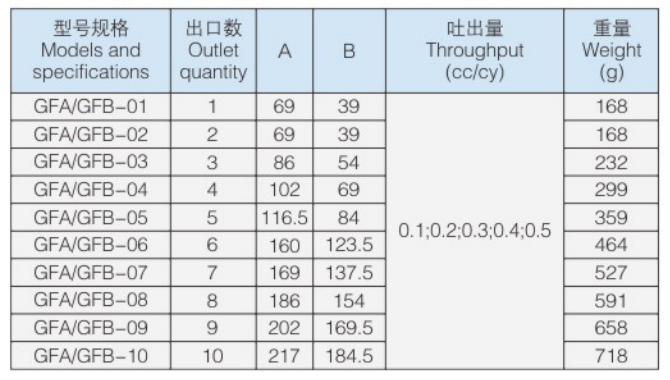

1.Oil volume is indicated as follows (Notes: When oil volume of all oil outlets is the same, only one oil volume level is indicated).

2.Example 1: GFA/GFB-05-2 means the oil ejection volumes of positions 1, 2, 3, 4 and 5 of the 5-position distributor , and oil ejection volume shall be 0.2mL/time.

3.Example 2: GFA/GFB-05-53235 means the oil ejection volumes of positions 1, 2, 3, 4 and 5 of the 5-position distributor, and oil ejection volume shall be 0.5, 0.3, 0.2, 0.3 and 0.5mL/time.

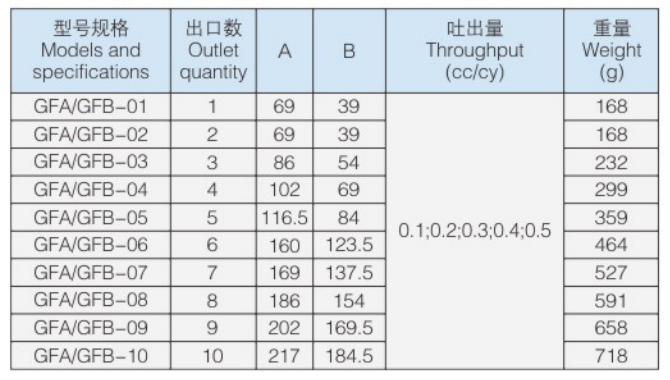

4.Applicable ambient temperature:-10℃ to 50℃ .

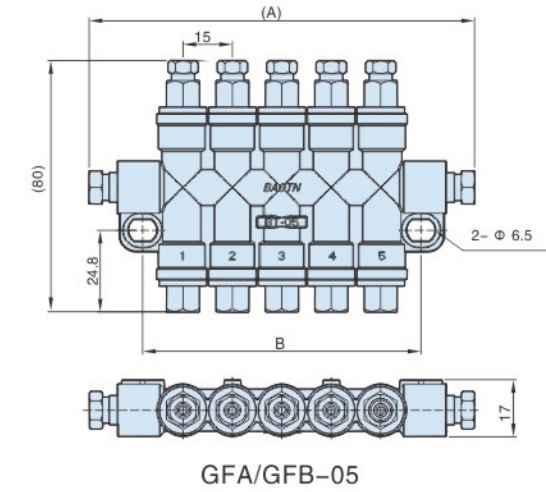

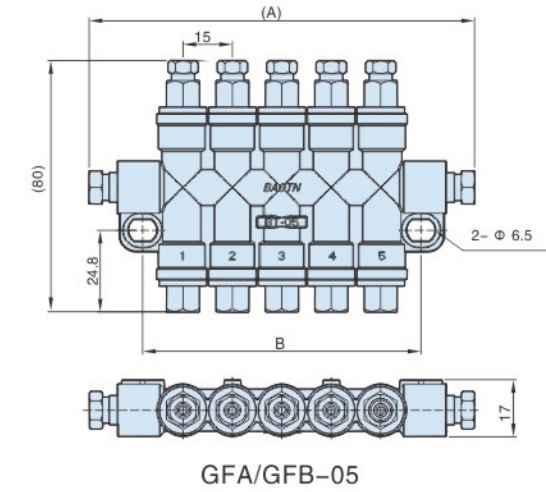

Schematic diagram of the GFA/GFB distributor

1.The lubricant conveyed from the oil injector shall be pulled up from the umbrella valve in the GFA/GFB distributor. When the umbrella valve seals the oil outlet port, the oil pressure forces GFA/GFB oil storage block to overcome the spring force to lower the oil level, and the oil cavity starts to store oil.

2.When GFA/GFB oil storage block is pushed to the top of the oil cavity, oil storage of the GFA/GFB is completed. 3.When the oil pump stops supplying oil, the unloading valve is opened automatically, and the main oil pipe injects oil into it, and the system pressure is lowered down. The umbrella valve resets and seals the inlet oil, and the GFA/GFB oil storage block starts to eject lubricant in the oil cavity.

The GET series centralized lubrication system is a high pressure grease lubrication system,designed,developed and manufactured by BAOTN Intelligent Lubrication Technology (Dongguan) Co., Ltd. for various large and medium-sized machinery. It is suitable for electric power, mining, metallurgy, machine tools, textiles, food, ports, commercial vehicles, construction machinery, heavy machinery and equipment and other industries to ensure the lubrication performance of various mechanical products and extend the service life and accuracy of mechanical equipment.