Automatic oil lubrication pumps, like BAOTN’s BT-C2P4, help your machines last longer in metal processing. These pumps put oil exactly where it is needed. This helps your machines work well and last longer. You can stop expensive breakdowns and keep your machines running. There is less time when machines are not working. Advanced lubrication systems give you real-time checks, overheat safety, and double filters. The table below shows what many companies say about using automatic oil lubrication pumps:

Benefit | Description |

Reduced Downtime | Automated systems stop breakdowns, so machines stop less. |

Increased Worker Safety | No need for workers to add oil in dangerous places, so it is safer. |

Cost Savings | Saves money on fixing machines and wasted oil. |

When you pick automatic oil lubrication pumps, you keep your machines safe, save money, and make them last longer.

Key Takeaways

Automatic oil lubrication pumps, such as the BAOTN BT-C2P4, help machines work longer. They send oil exactly where it is needed.

These pumps lower downtime and cut maintenance costs. This lets machines run smoother and break down less often.

Real-time monitoring features warn you about possible problems. This helps your machines work well and stay safe.

Automatic lubrication systems make workers safer. They remove the need for people to oil machines in dangerous places.

Buying automatic lubrication pumps saves money on repairs over time. It also helps machines work better for longer.

Automatic Oil Lubrication Pumps in Metal Processing

How Auto Lubrication Pumps Work

An auto lubrication pump helps metal machines work well. The pump sends oil to each part that needs it. It takes oil from a tank and pushes it through tubes. Valves and injectors decide how much oil goes to each spot. The control system sets when and how much oil is sent. You do not have to stop machines to add oil by hand. The pump works with a vacuum, so oil moves fast and does not get stuck. It also changes pressure to keep oil flowing and stops air from mixing in.

Auto lubrication pumps stop mistakes and keep machines safe. You get the right amount of oil at the right time. This helps your machines last longer and wear out less.

You can use these pumps in many places:

These pumps help machines work without long stops. Workers stay safe because they do not need to add oil by hand.

Here is a table that shows the main parts of an auto lubrication pump:

Component | Description |

Reservoir | Holds oil before the pump sends it out |

Pump | Pushes oil through the system |

Feed lines | Carry oil to valves and injectors |

Metering valves | Decide how much oil goes to each part |

Injectors | Put oil in the right spot in the machine |

Control system | Runs the smart oil process and sets each cycle |

Key Features and Innovations

Smart lubrication has changed how you care for machines. The BAOTN BT-C2P4 pump has many new features. It gives each part the right amount of oil. You can see what the pump is doing at any time. Overheat protection keeps the pump safe from getting too hot. Two filters make sure only clean oil goes to your machines, which stops damage.

Here are some top features in new auto lubrication pumps:

Feature | Description |

Real-time Monitoring | Sensors check temperature, pressure, and flow for smart care and early fixes |

Overheat Protection | Stops the pump from getting too hot and leaking |

Control Panel | Lets you see the system and change settings easily |

Dual-layer Filtration | Keeps oil moving well and stops dirt from getting in |

Smart lubrication with the BT-C2P4 pump helps you worry less. Your machines get good oil and you do not pay for big repairs. These pumps save you time and money and keep your machines working great.

Longevity Benefits for Equipment

Reduced Friction and Wear

You want your machines to work well and last long. Automatic oil lubrication pumps help you do this. These pumps put oil on every moving part. This lowers friction and stops parts from wearing out. Your machines work better and break less often. You spend less time fixing them.

Here is a table that shows how automatic lubrication helps your machines last longer:

Benefit | Description |

Increases equipment efficiency | Less friction and wear. |

Ensures precise lubricant distribution | Less waste. |

Long-term stable operation | Easy care and low cost. |

Your machines stop less often because they do not break as much. Good lubrication makes machines last longer and saves money. You also see better performance every day.

Automatic lubrication systems do the job instead of people. You get oil where and when it is needed.

These systems lower wear in moving machines. You make machines last longer and stop less.

Smart lubrication uses special checks. You get better work and need less manual labor.

Overheating and Corrosion Prevention

Heat and rust can hurt your machines and make them last less. You need to keep your machines safe from these problems. Automatic oil lubrication pumps help keep machines cool and safe. Oil lowers friction and stops heat from building up. Regular oiling protects your machines from damage.

Automatic lubrication systems give steady oiling. You lower the chance of heat and rust.

You make machines last longer by stopping damage.

Smart pumps use special parts like diaphragm isolation and strong materials. You get protection from rust and better strength.

Here is a table that shows how good oiling helps stop rust:

Feature | Benefit |

Diaphragm Isolation | Stops pumped fluid from touching moving parts, so less rust. |

Corrosion-resistant Materials | PTFE, stainless steel, Hastelloy®, and titanium make machines stronger. |

High Accuracy and Leak-free | Oil goes where it should, so less chance of rust from leaks. |

Your machines work well and you avoid costly stops.

Consistent Lubrication and Fewer Errors

Adding oil by hand can cause mistakes. You might forget or use too much. Automatic oil lubrication pumps fix this. These pumps give steady oil every time. Real-time alerts and checks help you watch oil levels and quality.

Real-time checks stop more friction and wear. You lower the chance of sudden breaks.

Alerts tell you if oil is too high or low. You can fix it fast.

Sensors find problems in the system. Maintenance teams get told to fix things quickly.

Always checking means you only look at machines when needed. You save time and stop less.

Automatic lubrication systems give regular and exact oiling. You make fewer mistakes and help machines work better. Your machines get the right amount of oil, so they last longer.

Tip: Using automatic oil lubrication pumps helps you stop less, work better, and keep your machines safe for years.

Auto Lubrication Pump vs. Manual Lubrication

Efficiency and Reliability

Automatic oil lubrication pumps make machines work better. These pumps send oil to the right spot at the right time. You do not need to stop machines to add oil by hand. This keeps machines working and lowers downtime. Manual lubrication takes longer and can cause mistakes. Workers might forget a spot or use too much oil. This can make parts wear out faster.

Here is a table that shows how automatic and manual lubrication are different:

Aspect | Automatic Oil Lubrication Pumps | Manual Lubrication Methods |

Efficiency | Gives steady, exact oiling and lowers wear and stops. | Takes more time and can have mistakes. |

Maintenance | Needs less care; easy to watch and fix. | Needs lots of checking and hand work. |

Cost | Costs more at first but saves money later. | Cheaper at first but costs more over time. |

Safety | Keeps workers away from dangerous places. | Workers must go to risky spots. |

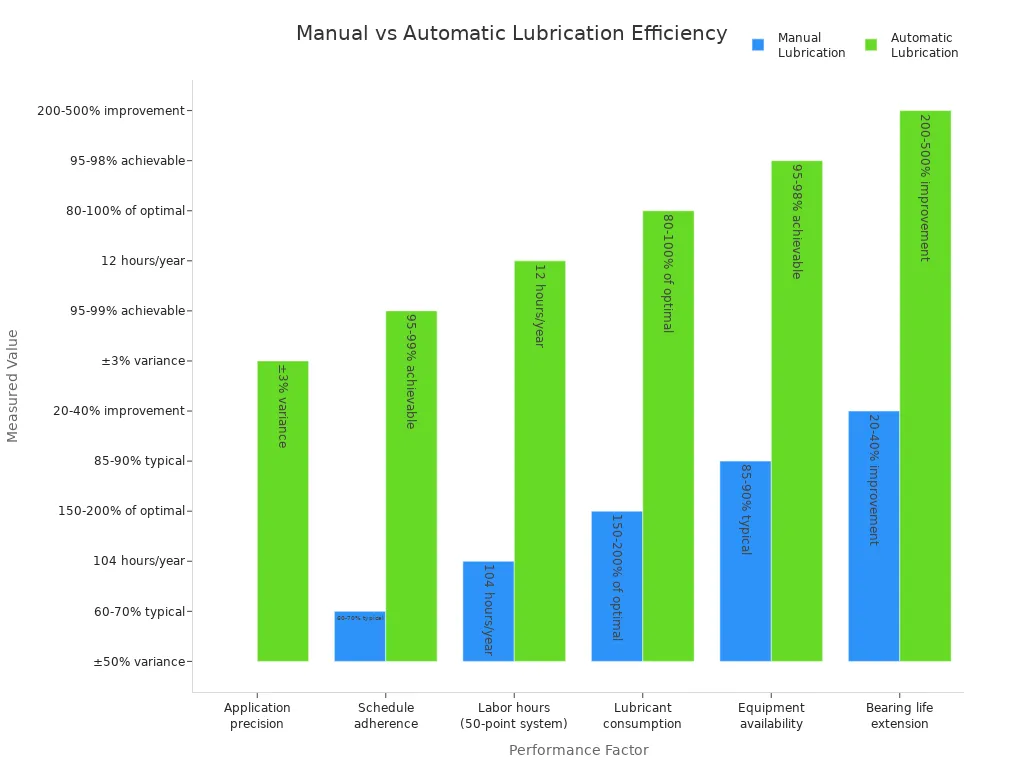

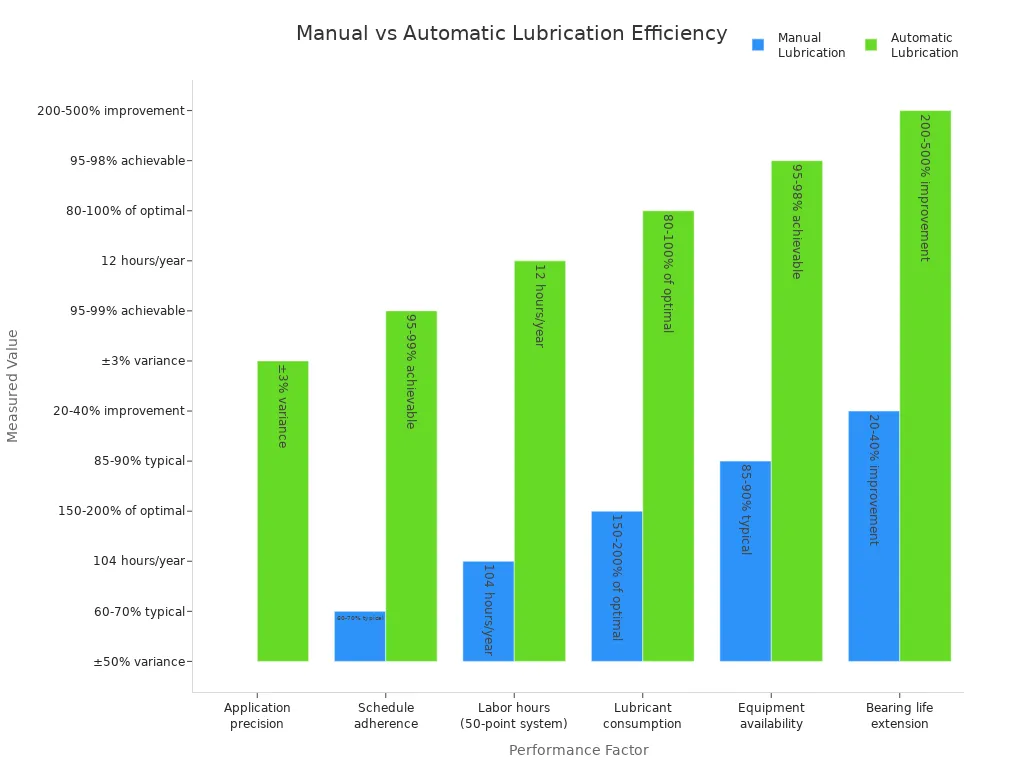

Automatic pumps help you follow your schedule almost all the time. Manual ways do not work as well. Bearings last longer and machines are ready more often. Look at this chart to see how they compare:

Automatic lubrication systems keep workers safe. They do not need to go to dangerous places, so accidents happen less.

Maintenance and Cost Savings

You save time and money with automatic lubrication. These systems use less oil and keep machines working well. You do not need to check or add oil as much. This means fewer jobs and less chance to miss a spot. You also lower the risk of machine breaks, which cost a lot to fix.

Automatic pumps help you fix problems before they get bad. They watch your machines and warn you early.

You stop less because machines get oil while working.

Many companies save thousands each year. They use less oil and pay less for repairs.

Here is a table that shows how automatic lubrication helps with maintenance:

Benefit | Description |

Continuous Lubrication | Gives oil all the time while machines work. |

Minimized Wear | Lowers friction and wear, so parts last longer. |

Reduced Downtime | Machines stop less and parts last longer. |

Optimized Lubricant Distribution | Oil goes to moving parts and spreads well. |

Monitoring | Watches oil and warns workers about problems. |

Automatic oil lubrication pumps help machines last longer. They also make work safer and easier. This helps your business run smoothly and get better results.

You can make your metal machines last longer with automatic oil lubrication pumps like BAOTN’s BT-C2P4. These pumps put oil in the right spot. This helps parts wear out less and machines work better. Experts say you should use filters and store oil the right way. You also need to check oil often to keep it clean. When picking a pump, look at how much oil it gives, if it fits your machines, and how much it costs. More factories now use smart pumps. This helps you control machines better and save money. Look at your machines now and think about getting new pumps to stay ahead.

FAQ

How often do you need to check an automatic oil lubrication pump?

You should check the pump’s status weekly. Most pumps, like the BT-C2P4, have real-time alerts. These alerts help you spot problems early. Regular checks keep your machines safe and running well.

Can you use automatic oil lubrication pumps on any metal processing machine?

You can use these pumps on most metal processing machines. They work well with CNC machines, presses, and forming equipment. Always check the pump’s specs to make sure it fits your machine.

What happens if the oil runs low in the pump?

Most pumps have a liquid level switch. This feature warns you when oil is low. You get an alert so you can refill the oil before it causes damage.

Do automatic pumps save money over time?

Yes! You save money because the pump uses oil wisely and reduces wear. You also spend less on repairs and downtime. Many companies see big savings after switching to automatic pumps.

How do you know if the pump is working correctly?

Look for indicator lights or alerts on the control panel.

You can also listen for unusual sounds or check for leaks. Regular monitoring helps you catch issues early.