Centralized lubrication system refers to a system that distributes the required lubricating oil and grease to multiple lubrication points, including the transportation, from a lubricating oil supply source through some distributors to distribute the pipeline and the oil quantity measuring parts. , distribution, conditioning, cooling, heating and purifying lubricants, as well as complete systems for indicating and monitoring parameters such as oil pressure, oil level, differential pressure, flow and oil temperature and faults.

The centralized lubrication system solves the shortcomings of traditional manual lubrication. It can provide lubrication at regular, fixed point and quantitative basis during mechanical operation, which minimizes the wear of the parts and greatly reduces the amount of lubricant used. At the same time of energy saving, the loss of the parts and the maintenance time are reduced, and finally the best effect of improving the operating income is achieved.

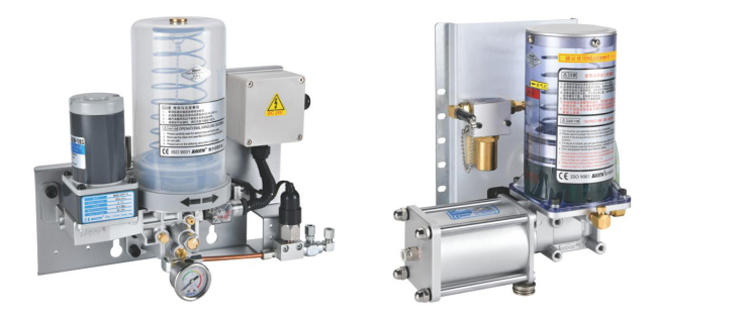

According to the lubrication pump oil supply mode,the centralized lubrication system is divided into the manual lubrication system and the automatic electric lubrication system ; according to the lubrication method, it can be divided into the intermittent lubrication system and the continuous lubrication system; according to the transportation medium, It can be divided into grease centralized lubrication system and thin oil centralized lubrication system; according to lubrication function, it can be divided into resistive centralized lubrication system and volumetric centralized lubrication system; according to the degree of automation, it can be divided into ordinary automatic lubrication system and intelligent lubrication system. The centralized lubrication system is currently the most widely used lubrication system, including full-loss and cyclic lubrication, such as throttle, single-wire, two-wire, multi-line and progressive.

Post time: Oct-09-2019